High-efficiency Alkaline Thickener, Mining Thickener Group Introduction

Product Description

Alkaline Thickener — Product Feature

1.Deaeration cell is provided to prevent solid particles from attaching to bubbles so that solid particles can fall like a parachute.

Alkaline Thickener — Product Application

It is widely used for dealing with slime, wastewater, waste residue in metallurgy, mine, coal, petrochemical industry, building materials, environmental protection department etc.

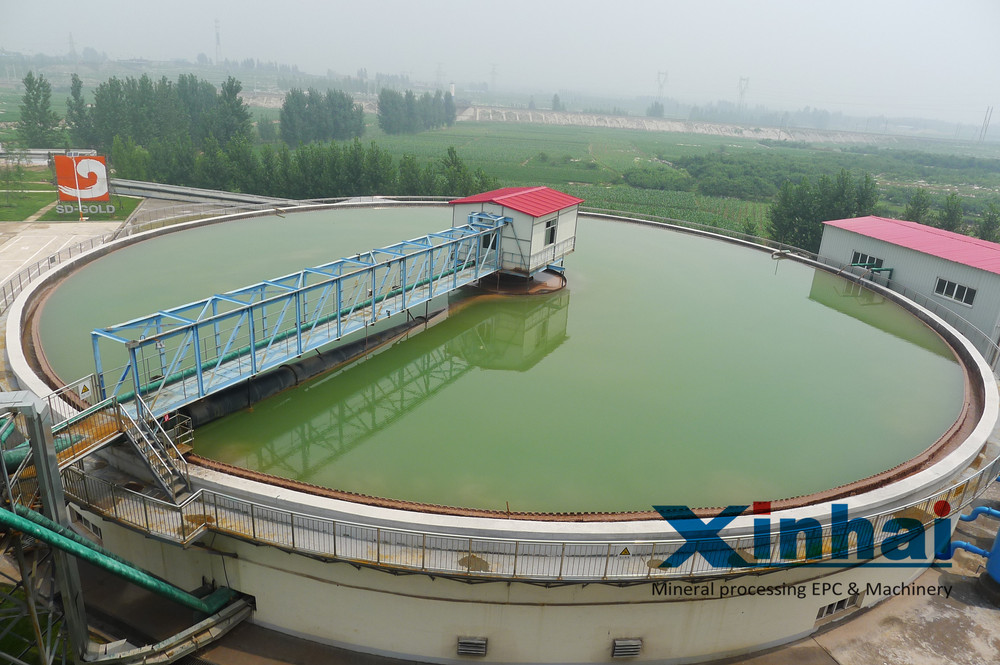

Alkaline Thickener — Product Principle

This thickener consists of round thickener and harrow scrapping machine, the solid particles suspend in thickener settling by gravity, the pulp in the upper turn into clean water, so that the separation can be realized. Slime that sediment in the bottom of the thickener is discharged by the harrow scrapping continuously, and clean overflow from the upside.

Alkaline Thickener — Technical Parameter

Model | D of the tank | Depth of the tank | Sedimental area | capacity | Motor model | Motor power |

NZSG-2.5 | 2500 | 1850 | 4.9 | 5-10.8 | Y90L-6 | 1.1 |

NZSG-3A | 3000 | 1800 | 7 | 5-23.3 | Y100L-6 | 1.5 |

NZSG-3 | 3600 | 10.2 | 5-28.5 | |||

NZSG-5 | 5000 | 2956 | 16 | 16-90 | Y90L-4 | |

NZSG-6 | 6000 | 28.3 | 98 | |||

NZSG-7 | 7000 | 3000 | 38.5 | 140 | Y112M-6 | 2.2 |

NZSG-8 | 8000 | 3318 | 50.2 | 185 | Y132S-6 | 3 |

NZSG-9 | 9000 | 3376 | 63 | 210 | ||

NZSG-12 | 12000 | 3600 | 113 | 370 | ||

NZSG-15 | 15000 | 4000 | 176 | 580 | Y132(M2)-6 | 5.5 |

NZSG-18 | 18000 | 4400 | 255 | 960 | YCT200-413 | 7.5 |

NZSG-20 | 20000 | 4400 | 315 | 1400 | Y160(M2)-8 |

Group Introduction

Xinhai Group founded in 1993 has grown into the industry group involving mineral processing, wearable rubber, mining investment and LFC Machinery after twenty years development. We have been always committed to providing customers with professional, perfect, efficient equipment and solutions. The whole solution we provide for you with the core of reliable & efficient mineral processing schemes and environmental-protection & energy-saving tailings dry stacking, makes us stand up in every EPC bid.

Our Customers

Our Factory

How To Contact Us?

Send your Inquiry Details in the Below for free sample,Click "Send" Now.

Product Categories : Thickening Equipment