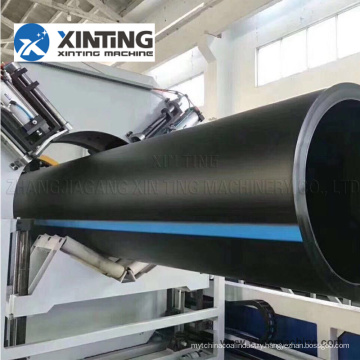

HDPE PE Pipe Making Machine/PPR Pipe Extrusion Production Line with Good Service

Product Description

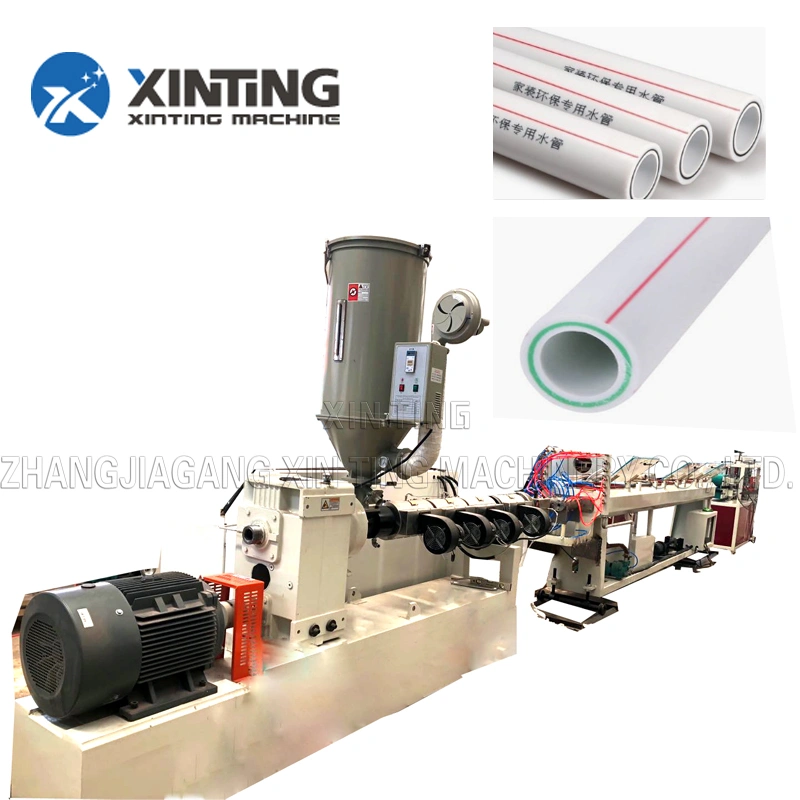

HDPE PE pipe making machine/PPR pipe extrusion production line with good service

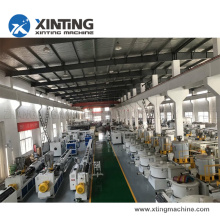

Main Features for plastic PE PPR pipe making machine

2) Adopting advanced famous brand components in pneumatic parts ,electric parts and operation parts.

3) Significant high out-put with low energy consumption.

4) Running in a high automatization and intellectualization.

PE PPR PIPE making machine Product Application:

1.The production line is suitable for producing small diameter single wall bellows with PP and PE raw materials. It can continuously produce polyethylene, polypropylene, polyvinyl chloride, Eva and other bellows and PA bellows.

2.It is used as wire and cable to wear pipe, washing machine drainage pipe, vacuum cleaner pipe and ventilator

3.It is widely used in automobile wire, electric wire pipe, machine tool circuit, lamp wire protection tube, air conditioner, washing machine and so on.

PE PIPE EXTRUSION LINE PARAMETERS | |||||

Model | Pipe range | Extruder | Max.output(kg/h) | Motor power | Total power |

PE-63 | 16-63mm | SJ65/33 SJ25/25 | 120-180 | 45KW | 110KW |

PE-110 | 16-110mm | SJ65/33 SJ25/25 | 150-200 | 55KW | 130KW |

PE-160 | 50-160mm | SJ75/33 SJ25/25 | 150-220 | 75KW | 150KW |

PE-250 | 75-250mm | SJ75/33 SJ25/25 | 280-350 | 90KW | 280KW |

PE-315 | 110-315mm | SJ90/33 SJ25/25 | 250-350 | 132KW | 350KW |

PE-450 | 160-450mm | SJ90/33 SJ25/25 | 350-450 | 160KW | 400KW |

PE-630 | 315-630mm | SJ120/33 SJ25/25 | 550-850 | 200KW | 550KW |

PE-800 | 450-800mm | SJ150/33 SJ25/25 | 800-1300 | 250KW | 750KW |

PPR PIPE EXTRUSION LINE PARAMETERS | |||||

Model | Pipe range | Extruder | Max.output(kg/h) | Motor power | Total power |

PPR-63 | 16-63mm | SJ65/33 SJ25/25 | 100 | 75KW | 32M |

PPR-110 | 50-110mm | SJ75/33 SJ25/25 | 200 | 145KW | 35M |

PPR-160 | 75-160mm | SJ90/33 SJ25/25 | 220-250 | 180KW | 35M |

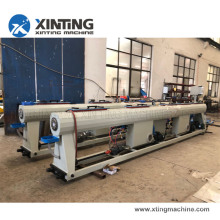

Process line:

Raw material + master batches→mixing→vacuum feeding →material dryness →single screw extruder→extrusion mould→corrugation forming machine→meter measurer→double winder→finished product inspecting &packing

This kind of pipe is high temperature resistance, anti-erosion, anti-abrasion and with high strength, the pipe can be used as oil pipe in automobile braking system, and for high temperature egas, chemical liquid transferring.

Features of PE HDPE corrugated pipe extruder product :

1.Plastic single-wall corrugated pipes have features of high temperature resistance, resistant to corrosion and abrasion, high intensity, good flexibility, etc.

2.Molding corrugation pipe with smooth inside and outside surface,and even ripple at one time by corresponding die

Corrugated pipe production line Technical Parameter :

| Pipe diameter | 8-32mm | 16-75mm |

| Main Extruder model | SJ50 | SJ65 |

| Main Extruder L/D | 25:1/28:1/30:1 | 25:1/28:1/30:1 |

| Capacity | 30-50kg/h | 60-80kg/h |

| Main Motor | 11KW/15KW | 18.5KW/22KW |

| Cooling type | Air fans cooling | Air fans cooling |

| Forming mould quantity | 50 paris | 60 pairs |

| Production Speed | 8-12m/min | 8-15m/min |

| Forming machine motor | 1.5kw | 1.5kw |

PVC pipe making machine

Description of PVC pipe making machine :

PVC pipe extruder machine /PVC pipe making machine/PVC pipe extrusion line is mainly used in the manufacture of the UPVC and PVC pipes with various tube diameters and wall thickness such as the agricultural and constructional plumbing, water supply and drain etc.

This set is composed of conical twin-screw extrude, vacuum calibration tank, haul-off machine, cutter, stacker etc. The screw extruder and traction machine adopt imported AC frequency control device. The vacuum pump and traction motor both adopt advanced products. The haul-off machine has many models, such as two-claw, three-claw, four-claw, six-claw etc. It may choose visual blade or cutting type.The unit is of reliable performance and high production efficiency.

Our machine can produce the PVC pipe with diameter from 16mm to 630mm

Main parameter of PVC pipe making machine

Mode

| Pipe range (mm) | extruders

| Max. output (kg/h) | Max. speed (m/min) | Total power (kw) | Line length (m) |

PVC-50x2 | 16-50 | SJSZ51/105 | 150 | 6m | 60w | 20m |

PVC-63 | 16-63 | SJSZ45/90 | 120 | 10m | 45w | 20m |

PVC-110 | 50-110 | SJSZ51/105 | 150 | 6m | 60w | 24m |

PVC-160 | 63-160 | SJSZ65/132 | 300 | 5m | 100w | 24m |

PVC-250 | 110-250 | SJSZ80/156 | 400 | 3.5m | 120w | 28m |

PVC-315 | 160-315 | SJSZ 80/156 | 400 | 3m | 160w | 28m |

PVC-450 | 250-450 | SJSZ 92/188 | 700 | 1.5m | 200w | 36m |

PVC-630 | 315-630 | SJSZ92/188 | 700 | 0.9 | 230kw | 36m |

plastic pipe punching machine

pastic pipe screw making machine

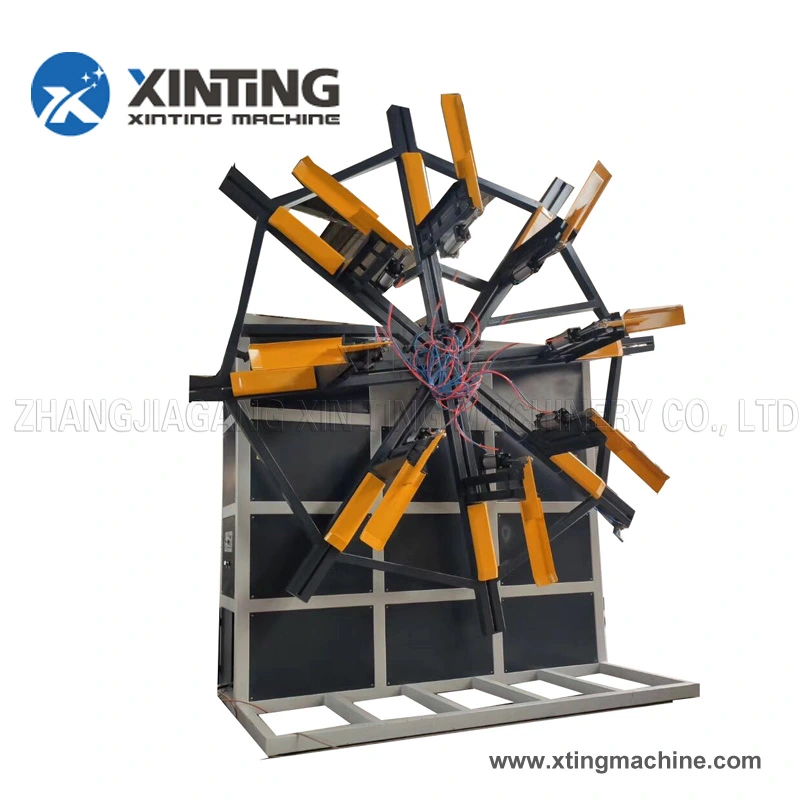

coiling winding machine

1) It is mainly used for winding PE pipe,PE aluminum pipe,corrugated pipe,and other some pipe or profiles.This pipe winding machine is highly automatic,and usually work with whole production line.

2) The plate is controlled by gas; winding adopt torque motor; with special equipment to arrange the pipe, this pipe winding machine can wind pipe well, and work much stable.

3) There are mainly model for this hose pipe winding machine: 16-40mm single/double plate pipe winding machine, 16-63mm single/double plate pipe winding machine,63-110mm single plate pipe winding machine.

Model of Full automatic Single station winder machine:

Model | DS32 | DS63 | DS110 |

Suitable pipe diameter | 16-32 | 32-63 | 63-110 |

Winding speed | Automatic adjusting according to pipe extrusion speed | ||

Winding inner diameter | Adjustable | ||

Winding width of roll | Adjustable | ||

Winding arrangement | Automatic displacer | ||

Discharge of roll | Pneumatic drive | ||

Note:For big pipe winding machine,such as Φ160mm pipe,we need special design and take your special order.

plastic PVC pipe belling expansion machine

Techiniacal Parameter

SGK-160 |

|

Pipe diameter: | Φ50-Φ160 |

Pipe length: | suitable for different pipe length |

Production speed: | 20PCS/H |

Max. Heating temp.: | 300° |

Oil pump power: | 1.5kw |

Machine working air pressure: | 4-6.3MP |

Hydraulic oil | 46# wearable oil |

Air compressor power: | 0.4-0.6Mpa |

If cooling by water pressure | 0.2-0.3MPa |

Intsll power: | 9.5kw(single oven), 20.5KW(double oven) |

With PLC control: | FX1n-60MR |

Electricity: | 380V 50HZ 3P(according to client request) |

Dimension: | 6400×1550×1700mm |

Machine weight: | 3.6T |

Product Categories : 06.PE pipe production line > Others 06.PE pipe production line

Premium Related Products