300tpd China Gold Mining Equipment/ Gold CIL Plant Group Introduction

Product Description

300tpd China Gold Mining Equipment- Gold CIL Plant

Yantai Xinhai offers turnkey solutions for 300tpd Gold Mining Equipment- Gold CIL Plant. We are one of the leading project suppliers for 300tpd Gold Mining Equipment- Gold CIL Plant and we work closely with our customers to fulfill their specific needs for a customized packaged solution. Specialized in the fabrication of these machines for18 years and this enables us to be in a leading position in the field of 300tpd Gold Mining Equipment- Gold CIL Plant .

We have been in 300tpd Gold Mining Equipment- Gold CIL Plant for more than18 years. We have established a great deal of experience in recent years developing Small Gold Mining Equipment .Our 300tpd Gold Mining Equipment- Gold CIL Plant line mainly include following equipment:

Feeder

Belt conveyors

Ball mill

Spiral classifer

Hydrocyclone

Thickener

Leaching Tanks

Electrowinning and desorption device

Gold smelting furnace

Our 300tpd Gold Mining Equipment- Gold CIL Plant are extensively used in metallurgy, mine, chemistry, coal, building material and grinding material industries.

Yantai Xinhai services:

Ore laboratory test Ore beneficiation test Flowchart designing and layout designing.Full set of machines Erecting and commissioning Training Technical consolation

300tpd Gold Mining Equipment— Gold CIL Plant turnkey project contents:

1. Project engineering design

The project engineering design includes the whole beneficiation flowsheet from the beginning of raw ore plie in the plant to the tailing transportation, general layout drawing, transportation in the plant, electricity power, automation, water supply and drainage, civil construction, foundation, technical economy and so on. The design drawings and documents will be sent to the buyers after the design was finished. This design only includes the Gravity Separation plant inside. The roads out of plant, the pipeline from the water source area to the plant, outside power system to transformer in the plant are not included.

2.Equipment manufacture and supply

We can supply the whole line of gold leaching plant, including:

a. crushing system

b. grinding and classification system

c. leaching system

d. desorption and electrowinning device

e. gold smelting system

Seller confirms the requested mechanical equipments in the whole plant during the project engineering design. After offer the detailed equipments list to the buyer for the confirmation, the seller produces the main equipments and purchases the auxiliary equipments.

3. Package and delivery

Seller makes a classification package plan for all the kinds of equipments and materials. Transport the goods Sudan port.

4. Installation

(1)Manufacturing and installation of process metal structures of the plant:

Including steel hopper, steel chute, steel platforms for operation and steel support; excluding civil engineering, steel structure platform and steel structure work of the workshop.

(2)Manufacturing and installation of process pipelines of the plant:

Mainly including pipelines of slurry, water, gas and reagent, valves, elbows, flanges and fasteners; water pipelines excluding parts from water source to the plant, tailings pipelines excluding parts from exit of tailings pipe to tailings dam.

(3)Manufacturing and Installation of distribution boards and operation control cabinets, laying of electric wire and cable, lighting fixtures.

If distance between switch house and plant is more than 3m, will be charged in addition. Excluding switch house, including but not limited to transformer, inlet wire, high-low voltage distribution boards in switch house.

The installation work done by seller includes: installation for all kinds of main and accessory equipments of plant, plant electric fitting after transformer or generator, power distribution equipments and lighting system, electric wire and cable, all pipelines of water supply and drainage and ore slurry, nonstandard device manufacturing on site, service platform, handrail and ladders (exclude steel construction).

The seller provide installation instrument, offer the above kinds of installation requested materials, labors, welding rods and paints during installation. All kinds of pipelines, valves, steel materials, electricity wires, electric cables, lamps and electrical power box, switch, the power distribution cabinets are included in the installation materials.

The buyer should supply electric, crane, oxygen and ethyne during installation.

The transformer, water supply pipelines from water source place to beneficiation plant and tailings pipelines from beneficiation plant to tailing pond are out of the duty of the installation.

The installation staff according to the project schedule arrive at the site in batches.

5. Commissioning

The seller will be in charge of guiding the whole beneficiation plant line machinery without loading and the load test running for achieving the perfect status to meet the design targets and output.

The buyer will undertake the water, electric, steel balls, ore, lubrication oil and grease, cleaning instruments and so on needed during commissioning.

6. Personnel training

Seller trains the buyer’s managers, technicians and operators to operate the equipments and automation system and control the processing independently, and to manage the plant, maintain the equipments and accept the training of safety knowledge; confirm the contents of the item descriptions one by one in accordance with the contract requirements of the project, transfer all the technical documents and deliver the plant to the buyer.

7. other notes

The foundation, workshop, civil construction and tailing pond will be done by the local company entrusted by the buyer according to the drawing& design provided by the seller.

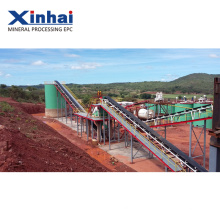

300tpd Gold Mining Equipment- Gold CIL Plant ON SITE

PRINCIPLE FLOWSHEET of 300tpd Gold Mining Equipment- Gold CIL Plant

Please kindly tell me your mine processing capacity (tons per day) and your ore properties, we will design the most efficient plant for you.

Group Introduction

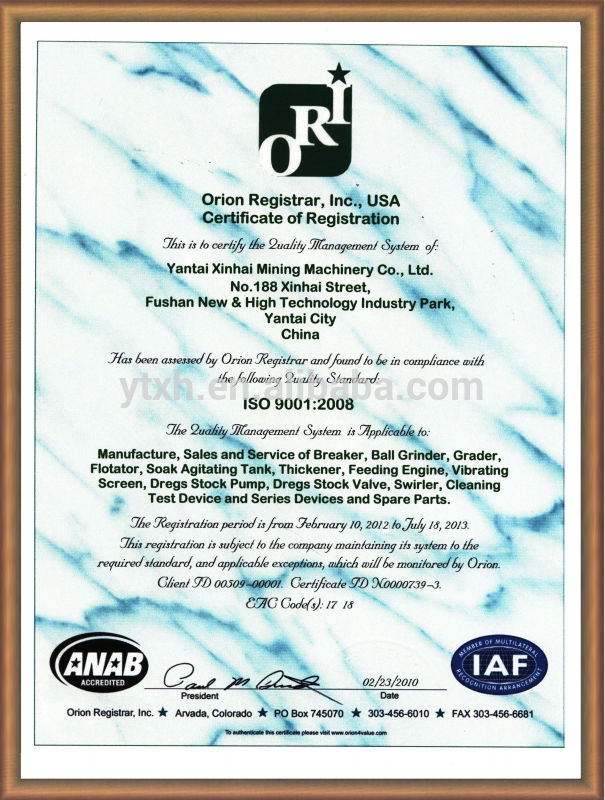

Xinhai Group founded in 1993 has grown into the industry group involving mineral processing, wearable rubber, mining investment and LFC Machinery after twenty years development. We have been always committed to providing customers with professional, perfect, efficient equipment and solutions. The whole solution we provide for you with the core of reliable & efficient mineral processing schemes and environmental-protection & energy-saving tailings dry stacking, makes us stand up in every EPC bid.

How To Contact Us?

Send your Inquiry Details in the Below for free sample,Click "Send" Now.

Our company has many other products for you reference as following:

2.Grinding Machinery

3.Screening Machinery

4.Flotation Machinery

5.Magnetic Equipment

6.Thickening Equioment

7.Filtration Equipment

8.Gravity Separation Equipment

……

Warmly welcome to visit our factory and company any time you like it!

Contact us if you need more details on Gold Mining Equipment. We are ready to answer your questions on packaging, logistics, certification or any other aspects about China Gold Mining Equipment、Small Gold Mining Equipment. If these products fail to match your need, please contact us and we would like to provide relevant information.Product Categories : Mineral Processing Plants

Premium Related Products