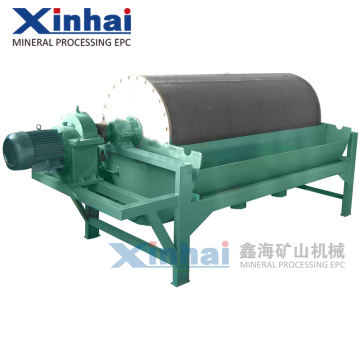

CT Dry Magnetic Separation Iron Ore , Magnetic Drum Separator Group Introduction

Product Description

CT Dry Magnetic Separation Iron Ore , Magnetic Drum Separator

Magnetic Drum Separator —Product advantages

1.Magnetic field intensity is 250-450mT.

2.Drum surface is covered with porcelain or LNT abrasion resistant rubber with long life expectancy.

3.Feeding iron grade is improved by greatly removing gangue.

1. Magnetic field intensity is 250-450mT.

2. Drum surface is covered with porcelain or LNT abrasion resistant rubber with long life expectancy.

3. Feeding iron grade is improved by greatly removing gangue.

4. Greatly improving the handling capacity, reducing milling cost, remarkable economic advantage.

5. Small revise brings big surprise

6. Specially used in preselecting and removing gangue when discharging coarse particles (0~18mm)

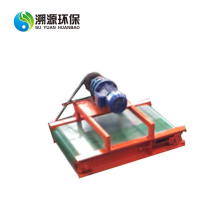

Magnetic Drum Separator — Product application

Magnetic Drum Separator — Product principle

After fine particle ores (18~0mm) are fed into the tank of Magnetic Separator, they enter magnetic selection area under the influence of the water flow spurted from sparge pipe. The magnetic particles are absorbed to the drum surface because of magnetism of magnetic body and rising with the drum. When magnetic particles are taken to the discharging area by drum, the wash water pushes them into the magnetic product trough. Under the action of ore pulp flow in the trough, the non-magnetic materials flow into non-magnetic product pipe through the hole of baseboard.

Model | Drum dimensions | Average drum surface magnetic intensity at ore separating area (mT) | Rotating speed of the drum | Separation particle size | Capacity | Motor model | Motor power | Weight |

CT2-66 | φ600×600 | 250-450 | 42 | 0-16 | 8-15 | XWD1.5-4-35 | 1.5 | 825 |

CT2-69 | φ600×900 | 12-20 | XWD2.2-4-35 | 2.2 | 999 | |||

CT2-79 | φ750×900 | 35 | 0-18 | 15-30 | XWD3-4-43 | 3 | 1375 | |

CT2-712 | φ750×1200 | 20-40 | 1834 | |||||

CT2-99 | φ900×900 | 31 | 25-50 | XWD-4-4-47 | 4 | 1540 | ||

CT2-912 | φ900×1200 | 30-60 | 2053 | |||||

CT2-916 | φ900×1600 | 35-75 | XWD5.5-4-47 | 5.5 | 2637 | |||

CT2-1010 | φ1050×1000 | 21 | 40-80 | XWD7.5-4-71 | 2700 | |||

CT2-1015 | φ1050×1500 | 50-100 | 7.5 | 3300 | ||||

CT2-1020 | φ1050×2000 | 60-120 | 5400 | |||||

CT2-1212 | φ1200×1200 | 17 | 80-150 | XWD7.5-4-87 | 5325 | |||

CT2-1218 | φ1200×1800 | 100-180 | 5700 | |||||

CT2-1224 | φ1200×2400 | 150-220 | XWD11-4-87 | 11 | 6500 |

Group Introduction

Xinhai Group founded in 1993 has grown into the industry group involving mineral processing, wearable rubber, mining investment and LFC Machinery after twenty years development. We have been always committed to providing customers with professional, perfect, efficient equipment and solutions. The whole solution we provide for you with the core of reliable & efficient mineral processing schemes and environmental-protection & energy-saving tailings dry stacking, makes us stand up in every EPC bid.

Our Customers

How To Contact Us?

Send your Inquiry Details in the Below for free sample,Click "Send" Now.

Product Categories : Magnetic Separator

Premium Related Products