Professional manufacturers magnetic separation technology , magnetic separation technology price Group Introduction

Product Description

Professional manufacturers magnetic separation technology , magnetic separation technology price

magnetic separation technology—Product advantages

1.Steady performance

2.High automaticity

3.Safe and reliable

4.Easy operation

magnetic separation technology— Product feature

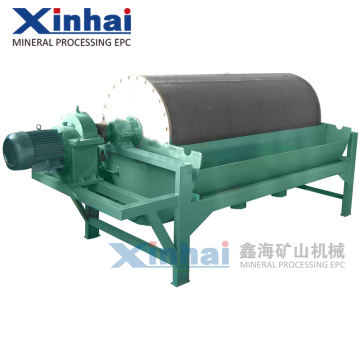

Semi-counter-current wet permanent magnetic drum separator

Product features: the scavenging area is shorter than counter-current tank and the dewatering area is longer than fair current tank. Therefore, it has high recovery rate and concentrate grade.

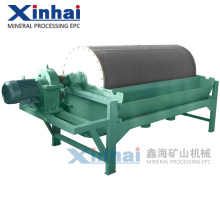

Counter-current wet permanent magnetic drum separator

Product features: with a long scavenging area, and the high recovery rate and low grade tailings can be obtained even the capacity is large.

Fair-current wet permanent magnetic drum separator

Product features: dewatering area is short.

magnetic separation technology— Product application

Semi-counter-current wet permanent magnetic drum separator

Range of application: mainly used for cleaning, and especially suitable for the minerals with particle size less than 0.15mm.

Counter-current wet permanent magnetic drum separator

Range of application: with high recovery rate, suitable for roughing, scavenging and heavy medium recovery.

Fair-current wet permanent magnetic drum separator

Range of application: apply to coarse particles or ores with low magnetic susceptibility, suitable for roughing and cleaning.

Semi-counter-current wet permanent magnetic drum separator

Working principle: slurry is fed into cavity from the bottom of drum, and the magnetic ores fall into concentrate tank after reaching a certain height, while the non magnetic ores will enter into tailings tank along with slurry in the opposite direction with drum.

Counter-current wet permanent magnetic drum separator

Working principle: slurry flows over against drum, which create great conditions for cleaning of non magnetic ores. The non magnetic ores approach the clean surface of drum and the magnetic ores can be absorbed in the strongest magnetic field.

Fair-current wet permanent magnetic drum separator

Working principle: slurry flows in the same direction with drum.

magnetic separation technology—parameter

Model | Drum dimensions | Average value of magnetic induction of the drum surface at ore separating area (mT) | Rotating speed of the drum (r.p.m) | Feed particle size (mm) | Capacity (t/h) | Motor model | Motor power (kw) | W (kg) |

CTB-69 | Φ600×900 | 145-180 | 40 | 00.2 | 815 | Y90L-4 | 1.5 | 981 |

CTN-69 | 00.6 | 780 | ||||||

CTS-69 | 06 | 830 | ||||||

CTB-612 | Φ600×1200 | 00.2 | 1020 | JTC561 | 2.2 | 1050 | ||

CTN-612 | 00.6 | 990 | ||||||

CTS-612 | 06 | 960 | ||||||

CTB-618 | Φ600×1800 | 00.2 | 1530 | JTC561A | 2 | 1390 | ||

CTN-618 | 00.6 | 1330 | ||||||

CTS-618 | 00.6 | 1340 | ||||||

CTB-712 | Φ700×1200 | 155-180 | 35 | 00.2 | 1530 | JTC562A | 2.8 | 1510 |

CTN-712 | 00.6 | 1530 | 1500 | |||||

CTS-712 | 00.6 | 1530 | 1460 | |||||

CTB-718 | Φ700×1800 | 00.2 | 2045 | 1579 | ||||

CTN-718 | 00.6 | |||||||

CTS-718 | ||||||||

CTB-918 | Φ900×1800 | 165-180 | 28 | 00.2 | 2555 | XWD4-7-35 | 4 | 4000 |

CTN-918 | 00.6 | |||||||

CTS-918 | 06 | |||||||

CTB-930 | Φ900×3000 | 00.2 | 52100 | XWD5.5-7-43 | 5.5 | 4280 | ||

CTN-930 | 00.6 | XWD5.5-7-43 | ||||||

CTS-930 | 00.6 | XWD5.5-7-43 | ||||||

CTB-1018 | Φ1050×1800 | 20 | 00.2 | 4080 | YCT280-5.5-19.2 | 3807 | ||

CTN-1018 | 00.6 | YCT280-5.5-19.2 | ||||||

CTS-1018 | 00.6 | YCT280-5.5-19.2 | ||||||

CTB-1021 | Φ1050×2100 | 00.2 | XWD5.5-7-43 | 3921 | ||||

CTN-1021 | 00.6 | |||||||

CTS-1021 | ||||||||

CTB-1024 | Φ1050×2400 | 00.2 | 52100 | 4404 | ||||

CTN-1024 | 00.6 | 5132 | ||||||

CTS-1024 | 4628 | |||||||

CTB-1030 | Φ1050×3000 | 160-180 | 00.2 | 120200 | XWD7.5-7-43 | 7.5 | 4431 | |

CTN-1030 | 00.6 | |||||||

CTS-1030 |

Group Introduction

Xinhai Group founded in 1993 has grown into the industry group involving mineral processing, wearable rubber, mining investment and LFC Machinery after twenty years development. We have been always committed to providing customers with professional, perfect, efficient equipment and solutions. The whole solution we provide for you with the core of reliable & efficient mineral processing schemes and environmental-protection & energy-saving tailings dry stacking, makes us stand up in every EPC bid.

Our Customers

How To Contact Us?

Send your Inquiry Details in the Below for free sample,Click "Send" Now.

Product Categories : Magnetic Separator

Premium Related Products