Professional manufacturers dewatering vacuum filter , dewatering vacuum filter price

Product Description

Professional manufacturers dewatering vacuum filter , dewatering vacuum filter price

dewatering ceramic filter — Product Introduction

A vacuum dewatering filter relying on microporous ceramic

dewatering ceramic filter — Product Improvement

Microporous ceramic as filtering medium saves cost by 90%

dewatering ceramic filter — Advantages

High vacuum degree (vacuum degree -0.09~-0.098MPa), low moisture of cakeHigh filtration precision, solid content of filtrate<50ppm, which can be recycle used in the system.

Energy saving up to 90%, low energy consumption, low running cost

Filter cake cleaning system is installed

PLC and computer integrate with automatic valve control; high degree of automation and low labor intensity

Compact structure; small area taken; convenient maintenance

Advanced drainage system ensures application in any running conditions

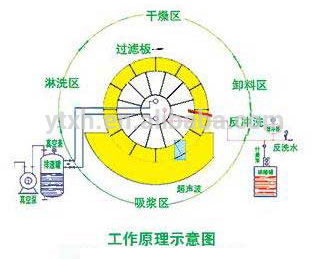

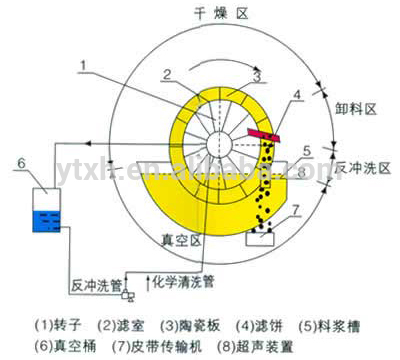

dewatering ceramic filter — Work Principle

Pulp absorbing area: filter plate immersed in the pulp while in operation produces a surface absorption of filter cake, with the action of capillarity and integrated with vacuum pressure. Filtrate enters distributing valve and drainage tank through filter plate.Spraying zone: filter cake receive spray washing after discharged from the slime hopper

Drying zone: continuous dewatering for filter cake is conducted with the action of high vacuum force.

Discharging zone: scraper will automatically discharge materials once entering the vacuum-free condition

Back Flushing: Service water or filtrate enters the ceramic plate through distributing valve and cleaning the blocked manhole. Cleaning with ultrasonic and low density acid after ceramic plate is used for one period to maintain the efficient service life of ceramic plate.

dewatering ceramic filter — Product Structure

Ceramic filter is mainly composed of roller system, stirring system, feeding& discharge system, vacuum system, filtrate discharge system, scraping system, washing system, combined cleaning (ultrasonic cleaning, automatic mixing acid cleaning) system, automatic control system, tank body and frames.

It can be widely used in concentrate and tailings dewatering of mining non-ferrous metals, rare metals, ferrous metal, and nonmetals. Dewatering of oxide, electrolytic slag, leaching residue, slag in chemical industry, sewage and mud disposal engineering and so on. The particle size of the materials can be realized from -200 to -450 meshes.

| Ore Types | Particle Diameter Distribution | Feeding Concentration | Capacity kg.(m2h)-1 | Water Content of Filter Cake% |

| Gold concentrate | -200~-325 mesh | 50~60 | 900~1500 | 6.5~11.5 |

| Gold tailings | -200~-400 mesh | 45~60 | 400~600 | 13~16 |

| Copper concentrate | -200~-325 mesh | 45~60 | 600~900 | 6.5~12 |

| Iron concentrate | -200~-325 mesh | 40~60 | 850~1500 | 6~10 |

| Zinc concentrate | -200~-325 mesh | 50~60 | 750~900 | 6.5~12 |

| Lead concentrate | -200~-400 mesh | 50~65 | 650~800 | 10~12 |

| Bauxite | -200~-325 mesh | 50~60 | 350~450 | 10.5~12 |

| Lead and zinc tailings | -200~-325 mesh | 50~65 | 350~550 | 12~16 |

| Cyanide residue | -325~-450 mesh | 50~60 | 350~550 | 21~24 |

| Sulfur concentrate | -200 mesh 80% | 50~65 | 350~790 | 8~12 |

| Nickel concentrate | -200~-325 mesh | 55~60 | 300~600 | 10~12 |

| Coal concentrate | -200 mesh 80% | 50~65 | 550~930 | 18~20 |

| Zinc oxide | -200 mesh 75% | 55~65 | 620~1200 | 8~12 |

| Fluorite powder | -200 mesh 60% | 55~65 | 750~900 | 8~12 |

| Model | Filtering Area/m2 | Filtering discs | Number of filtering plate | Tank volume/m3 | Installation power/KW | Operation Power/Kw | Main body(L×W×H)/m |

| TC-1 | 1 | 1 | 12 | 0.21 | 3.5 | 2.0 | 1.6×1.4×1.5 |

| TC-4 | 4 | 2 | 24 | 1.0 | 7.0 | 3.0 | 2.4×2.5×2.1 |

| TC-6 | 6 | 2 | 24 | 1.2 | 7.0 | 6.0 | 2.4×2.9×2.5 |

| TC-9 | 9 | 3 | 36 | 1.7 | 9.0 | 7.0 | 2.7×2.9×2.5 |

| TC-12 | 12 | 4 | 48 | 2.2 | 11.0 | 7.5 | 3.0×2.9×2.5 |

| TC-15 | 15 | 5 | 60 | 2.7 | 11.5 | 8.0 | 3.3×3.0×2.5 |

| TC-21 | 21 | 7 | 84 | 4.0 | 13.5 | 9.0 | 4.6×3.0×2.6 |

| TC-24 | 24 | 8 | 96 | 4.5 | 16.5 | 10.5 | 4.9×3.0×2.6 |

| TC-27 | 27 | 9 | 108 | 5.0 | 17.0 | 11.0 | 5.2×3.0×2.6 |

| TC-30 | 30 | 10 | 120 | 5.5 | 17.5 | 11.5 | 5.5×3.0×2.6 |

| TC-36 | 36 | 12 | 144 | 7.0 | 23.0 | 16.0 | 6.6×3.0×2.6 |

| TC-45 | 45 | 15 | 180 | 8.5 | 25.0 | 19.0 | 7.5×3.0×2.6 |

| TC-60 | 60 | 15 | 180 | 12.5 | 33.0 | 22.0 | 7.5×3.3×3.0 |

| TC-80 | 80 | 20 | 240 | 16.2 | 40.0 | 24.0 | 9.0×3.3×3.0 |

| TC-102 | 102 | 17 | 204 | 18.5 | 53.0 | 35.0 | 8.8×3.6×3.3 |

| TC-120 | 120 | 20 | 240 | 20 | 60.0 | 40.0 | 9.7×3.6×3.3 |

| TC-150 | 150 | 25 | 300 | 24 | 75.0 | 47.0 | 11.2×3.6×3.3 |

Xinhai mining was established in 1993.Adhering to the core concept of technology achievement future and technology as the first productivity, Xinhai pays close attention to technological innovation, and has built 6 professional technology institutes invested heavily to purchase advanced instruments and professional equipment. Xinhai has been the company with the most complete facilities and powerful technology in the domestic processing enterprises..

these are our factory and our office.

Technical personnel is doing experiments

Xinhai mining is committed to providing customers with professional, perfect and efficient products and services.Xinhai has projects all over the word,Indonesia,Africa,Armenia,Inner Mongolia Hailai,etc.Including EPC Project and many equipment.

these are our proect and our customers

Your email address and telephone will not be shared or published!

Please fill in your need products and your message and do not forget mail and/or phone if you like to be contacted.

we are the professional machine manufacturer in China.

I need to ask you some details for sending you the more suitable quotation,

1.what is the raw material do you want to process?

2.what is the capacity per hour do you need?

3.what is the raw material input size?

4.what is the output size of your product?

Request for Quotation

Of course, free live-chat is available and you can get help immediately.Or you can send me email .

You can get the price list and a Xinhai representative will contact you within one business day.

I hope you can tell me these details,i will give you the best quotation ASAP ,thanks. Your satisfaction is our greatest pursuit, we would like to sincerely for your service! We look forward to your inquiry!

Product Categories : Filtration and Dewatering Equipment

Premium Related Products