Professional manufacturers chute feeder , chute feeder price

Product Description

Professional manufacturers chute feeder , chute feeder price

1.Stable transmission; high working efficiency

2.Compact structure; reasonable design

3.Good quality; widely used

Chute feeder — Product feature

The chute feeder can be installed on the ground or hoisted on the discharge port of ore bin. The chute bottom plates do the reciprocating movement. Stroke can be adjusted by the eccentric wheel; the eccentric throw is half as big as the stroke. According to experience of some mine sites, the eccentric throw should be no less than 30mm for cohesive ore. The chute width is 2-2.5 times bigger than the maximum feeding granularity. The biggest chute feeder can supply ore with granularity less than 500mm.

The chute Feeder is used to convey mineral lump from storage silo to equipment in industries like smelting, mining, chemical, building material, concentrating and coal, etc.

Chute feeder — Product principle

The machine is usually installed underneath the discharging opening of ore bin. Minerals fall on the bushing. The bushing is located at the chute bottom, configured on idler wheel and via eccentric device connected with reducer which is linked to electric motor by coupler. When it works, electric motor drives reducer via coupler; eccentric disk and drain cap which is situated between chute frame bottom and roller begin to do reciprocal and linear motion so as to uniformly feed minerals.

Model | Outlet dimensions Width X Height (mm) | Max feed particle size (mm) | Feed capacity (t/h) | Motor model | Motor pwoer (kw) | W (kg) |

CG300×300 | 300×300 | 50 | 10--20 | Y90L- 4 | 1. 5 | 265 |

CG400×400 | 400×400 | 100 | 10--30 | Y112M- 6 | 2. 2 | 535 |

CG600×500 | 600×500 | 200 | 10--50 | Y112M- 4 | 4 | 1045 |

CG700×500 | 700×500 | 250 | 10--60 | 1100 | ||

CG1240×980 | 1240×980 | 350 | 36--90 | Y160M- 6 | 7. 5 | 1710 |

Note: The motor can be replaced by speed adjustment motor to adjust the feed ore amount according to the users requirements.

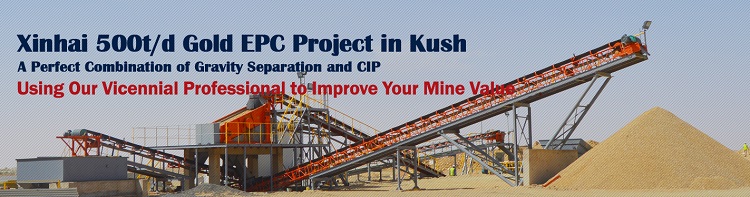

Kush Clients Consulting Mineral Processing

Clients of Kush project paid a special visit to Xinhai on Jan 18, 2014, for detailed communication with the Xinhai technicians. They made an estimate of the size , investment as well as earnings of the mill plant. During this meeting, based on rich experience of mineral processing and mill plant, Xinhai technicians wined the clients trusts for answering clients questions.

Kush Gold Mineral Processing Test

After the contract was signed, Clients posted to Xinhai two packages of samples, totally weight 400kg. Xinhai Mineral Processing Institute provided comprehensive mineral processing test after precious test.

The mineral processing test made an analysis to the gold content which is 4.31g/t, thus Xinhai technicians decided to recovery gold directly through the solution of CIP cyaniding, which including grinding the raw ore to 88.0% -200mush,and using lime as alkali, then adding sodium cyanide, agitating then leaching.The pulp density can reach 40%, 4kg/t of slime, 2kg/t sodium cyanide, the leaching rate of gold can get 91.45% which is perfectly good. While it was worth mentioning that the Institute noticed that if adding Gravity Separation, the recovery rate will not notably improved while increased the mineral processing cost. For the benefits of the customers, Xinhai technicians suggested cyaniding directly, while the customers firmly believed that with the deepen exploiting, the gold grade can increase to 8g/t, and considering finding large particles around the mine, technicians decided to adopt the solution of gravity separation + cyaniding the tailings after gravity separation.

Mine Design

Mine design, an vital part of Xinhai mineral processing EPC, was in charge of Xinhai Mining Design Institute with Class A Certification. For better suiting the actual situation of the project, technicians of the Mining Design Institute made field survey to the surroundings such as terrains, waters and power supply, then designed the construction drawing elaborately and gave 3D simulation based on the processing flowchart and the equipment selection mine processing test provided.

Installation & Commissioning

After the Equipment manufacturing and purchasing, the perfect packaging and delivery system can guarantee the security service.

Xinhai Installation & Commissioning Operation Center Project No.1 was in charge of as well as full participation the field installation & commissioning. On the one hand, they supervised the construction site to inspect any problems, on the other hand , they optimized the production and management process to improve interests for customers.

Xinhai mining was established in 1993.And was the pioneer of China beneficiation industry.Our company could provide mining machine more than 600,and have the most equipment in China.At present,Xinhai business includes Mineral Processing EPC,Wear-Resistant Rubber,LFC Machinery,and Mining Investment.

Q:Hi, are you mining machinery manufacturer?

A:Yes, we can also provide amples test, mine design, equipment manufacture, after-sale service, etc.

Q:which country have your products been exported?

A:Many country, such as India, Ethiopia and so on. And our company has agencies in Zimbabwe, Sudan and Tanzania.

Q:Can you do mineral processing test?

A:Yes, not only can do it in your country, also can back to our company

Your email address and telephone will not be shared or published!

Please fill in your need products and your message and do not forget mail and/or phone if you like to be contacted.

we are the professional machine manufacturer in China.

I need to ask you some details for sending you the more suitable quotation,

1.what is the raw material do you want to process?

2.what is the capacity per hour do you need?

3.what is the raw material input size?

4.what is the output size of your product?

Request for Quotation

Of course, free live-chat is available and you can get help immediately.Or you can send me email .

You can get the price list and a Xinhai representative will contact you within one business day.

I hope you can tell me these details,i will give you the best quotation ASAP ,thanks. Your satisfaction is our greatest pursuit, we would like to sincerely for your service! We look forward to your inquiry!

Product Categories : Feeding Equipment

Premium Related Products